|

|

|

|

2021年第12期 总第41卷 中英文目次 综述与评论 高职扩招背景下《液压与气动技术》教学改革探索 ........................................李瑞锋,杜 娟,李锦丽,等(1)

设计与研究 利用液体压差的自动换路阀门设计....................... 李 东,李启雄,邓仁俊(5) 新型速关调节阀抗冲击性能研究..........................闫玉曦,王东华,许宇健(9) 基于推移控制逻辑阀的液压支架推移控制系统优化研究................. 刘晓宾(13) 介质物性参数对核主泵水力性能的影响 ............................... 吕 雪,王秀勇,杜永峰,等(16)

三通流量阀与溢流阀的集成设计及应用.............. 向小强,王建成,李建松(21) 板坯连铸机动态轻压下液压伺服设备高效改造方案研究及应用实践 ......................... 张 伟,丘铭军,李向辉,等(25) 高性能纤维增强船用端面密封元件的应用设计与配方工艺研究 .............................................钱国会,耿艳春(38) 真空感应炉水乙二醇替换无水脂肪酸酯液压油研究 .......................................... 高 健,王秀君,刘 轩,等(43) 再论“液压变压器”应用前景.................................................... 郭仁发(46) 强压缸截止阀中液压油的流态分析..................... 姚泽功,王秀艳,刘 洋(50) 弯轴柱塞马达零排量功率损失分析..................................赵杏新,屠桂诚(55) 闭式液压系统在液驱往复式气体增压器上的应用........................... 罗 涛(57) 基于AMESim对液压系统低压告警仿真分析........ 金 磊,王勇彬,刘政宏(60) 大型垃圾压缩站用压缩油缸静应力分析........ 李勇键,吴俊逸,邓 昊,等(63) 平衡阀控制端阻尼对起重机卷扬抖动影响的研究 ........................................... 胡小冬,李会妨,刘莹莹,等(67) 液压系统的电气自动化控制设计................................................. 武兴瑞(70) 液压混合动力单元关键参数优化研究..............................郭志敏,董致新(74)

使用与维护 装卸料机C推杆泄漏率超标原因分析及处理.................................. 苗润泽(80)

新产品·新技术·新工艺 臂架缸底耳环焊后免镗工艺研究........................ 陈云周,易 鑫,吴俊逸(83) 一种高速高压离心泵的设计研究.................. 杨 凯,刘 伟,张红涛,等(88) 信息................................................................................... (20、42、79) 2021年《液压气动与密封》杂志总目次.................................................(91)

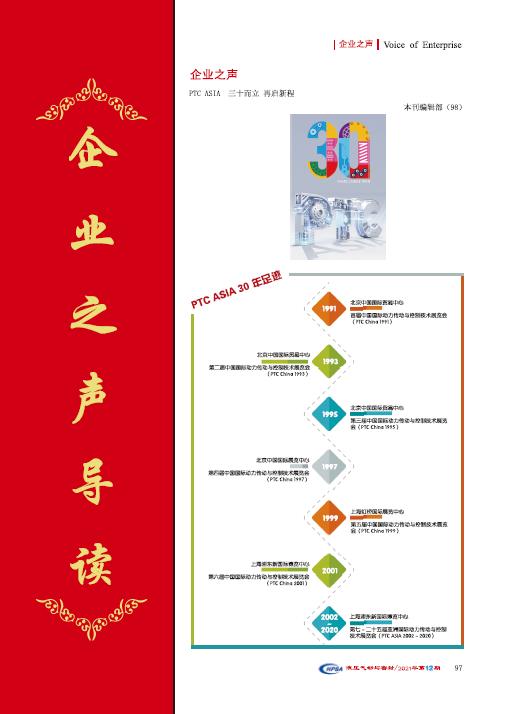

企业之声 PTC ASIA 三十而立 再启新程 ........................................ 本刊编辑部(98)

Application of Closed Circuit Hydraulic System for Reciprocating Gas Booster........... LUO Tao(57) Optimization of Key Parameters on Hydraulic Hybrid Unit.......... GUO Zhi-min, DONG Zhi-xin(74)

2021年第12期 总第41卷 李瑞锋,杜娟,李锦丽,龚佩芬,陈清 (陕西机电职业技术学院智能制造学院,陕西宝鸡 721001) 摘要:基于高职扩招学生无法到校学习的实际,针对《液压与气动技术》课程教学中存在的不足,结合扩招学生培养目标,通过重构线上教学资源,引进先进教学手段,优化课程实施以及改革考核方式等,进行了针对高职扩招学生的教学改革,探索了扩招学生的线下线上融合教学模式,教改方案经过试点,结果表明:教改效果良好,较好地解决了扩招学生无法到校学习的难题。该模式也可为后期的终身教育和开放式大学的线下线上融合教学提供参考。 关键词:高职扩招;液压与气动技术;线下线上融合;课程改革

中图分类号:TH137;G712文献标志码:A文章编号:1008-0813(2021) Exploration on Teaching Reform of ‘Hydraulic and Pneumatic Technology’ Under Enrollment Expansion of Higher Vocational Education LI Rui-feng, DU Juan, LI Jin-li, GONG Pei-fen, CHEN Qing (Department of Intelligence Manufacturing, Shaanxi Institute of Mechatronic Technology, Baoji 721001, China) Abstract: Based on the fact that the students in higher vocational colleges can not go to school to study, aiming at the shortcomings in the teaching of ‘hydraulic and pneumatic technology’, combining with the teaching objectives of students in higher vocational colleges, this paper carries out the teaching reform for the students in Higher Vocational Colleges by reconstructing the online teaching resources, introducing advanced teaching methods, optimizing the course implementation and reforming the assessment methods, This paper explored, offline and online integration teaching mode, and the experimental results show that the effect of the teaching reform was effective, which can better solve the problem that the expanded students can not study in school. This mode can also provide reference for the later life-long education and the online and offline integrated teaching of Open University. Key words: enrollment expansion of higher vocational education; hydraulic and pneumatic technology; offline and online integration; curriculum reform

李东,李启雄,邓仁俊 (四川航空工业川西机器有限责任公司,四川雅安625000) 摘要:根据某液压管路控制需要,总结了几种现有的自动控制阀门工作原理,参照普通压力滑阀原理,设计了一种利用进口管路压差驱动阀芯,自动实现油路切换的阀门。对该阀门进行受力分析得到在某些控制条件下阀门无法正常换路的设计缺陷,通过增加液压腔,对驱动力进行补偿设计,最终克服设计缺陷。 关键词: 滑阀;管路压差;液压腔;补偿设计

中图分类号:TH137文献标志码:A文章编号:1008-0813(2021) Design of Automatic Route Changing Valve Utilizing Liquid Pressure Difference LI Dong,LI Qi-xiong,DENG Ren-jun (Sichuan Aviation Industry Chuanxi Machinery Co., Ltd., Yaan625000, China) Abstract: Based on a certain hydraulic pipeline control needs, summarizing principle of several current automatic control values, referring to the principle of ordinary sliding valve, and design a kind of automatic route changing valve, which use inlet pipeline pressure difference to drive the core. Through the force analysis of the valve, a design defect was found that valve can not be changed normally under some control conditions. By adding a hydraulic chamber to increase the driving force, finally overcomes the design detect. Key words: sliding valve; pipeline pressure difference; hydraulic chamber; design detect

闫玉曦1,王东华2,许宇健2 (1.中国电建集团上海能源装备有限公司,上海201317; 2.上海船舶设备研究所,上海200031) 摘要:新型速关调节阀可精确调节蒸汽流量进而控制汽轮机转速,并能满足快速关闭的要求。该文根据速关调节阀实际工况建立有限元模型,介绍了其结构及工作原理,通过理论计算与有限元分析相结合的方法对速关调节阀关键零部件进行抗冲击性能研究,仿真结果与理论计算对比验证所得数据的有效性和准确性,并采用MATLAB拟合出不同方向下冲击载荷加载历程曲线,为进一步研究阀门结构强度及其使用寿命提供了必要的技术路径。 关键词: 速关调节阀、有限元分析,抗冲击、拟合曲线

中图分类号:TH137文献标志码:A文章编号:1008-0813(2021) Study on Impact Resistance of New Quick Closing Control Valve YAN Yu-xi1, WANG Dong-hua2, XU Yu-jian2 (1. Power China SPEM Limited Company, Shanghai201317, China; 2. Shanghai Marine Equipment Research Institute, Shanghai200031, China) Abstract: The new quick closing regulating valve can accurately adjust the steam flow and then control the turbine speed, and can meet the requirements of fast closing. In this paper, the finite element model is established according to the actual working conditions of the quick closing control valve, and its structure and working principle are introduced. The impact resistance of the key parts of the quick closing control valve is studied by the combination of theoretical calculation and finite element analysis. The simulation results are compared with the theoretical calculation to verify the effectiveness and accuracy of the data, The impact load loading history curves in different directions are fitted by MATLAB, which provides a necessary technical path for further study of valve structural strength and service life. Key words: quick closing regulating valve; finite element analysis; shock resistance; fitting curve

刘晓宾 (国家能源集团,山西忻州036600) 摘要:液压支架为煤矿综采面三机一体重要组成部分,实际使用中推移步距不等,液压系统控制精度低。通过推移逻辑控制阀,对电液控制系统推移流程进行优化,实现推溜及移架的精准控制,且消除了销轴间隙。由实验和实际应用可知,优化后控制系统可有效提高液压支架自动推移控制精度,确保了推移步距的一致性。 关键词: 煤矿;液压支架;综采面;推移控制;逻辑阀

中图分类号:TH137文献标志码:A文章编号:1008-0813(2021) Optimization of Hydraulic Support Pushing Control System with Pushing Control Logic Valve LIU Xiao-bin (National Energy Group, Xinzhou036600, China) Abstract: Hydraulic support is an important part of three machine integration in fully mechanized coal mining face. In actual use, the moving distance is not equal, and the control accuracy of hydraulic system is low. Through the pushing logic control valve, the pushing process of the electro-hydraulic control system is optimized to realize the precise control of sliding and moving, and eliminate the pin shaft clearance. It can be seen from the experiment and practical application that the optimized control system can effectively improve the control accuracy of the automatic pushing of the hydraulic support and ensure the consistency of the pushing step. Key words: coal mine; hydraulic support; fully mechanized mining face; pushing control; logic valve

吕雪1,王秀勇1,2,杜永峰1,汪东山1,黎义斌1,2 (1.兰州理工大学能源与动力工程学院,甘肃兰州730050; 2.甘肃省流体机械及系统重点实验室,甘肃兰州730050) 摘要: 为了研究介质物性参数变化对核主泵水力性能的影响,采用六面体结构化网格,基于RNG κ-ε湍流模型,在定常计算的基础上对比分析了输送介质分别为清水和液态钠时核主泵水力性能的变化。结果表明:介质物性参数的变化对泵内速度场的影响较小,但速度分布的均匀性随介质运动黏度的减小而降低;与水介质相比,当输送介质为液态钠时,核主泵的扬程变化很小,轴功率的下降幅度大于密度的减小幅度,因而效率提升明显。 关键词: 介质;物性参数;核主泵;水力性能;数值模拟

中图分类号:TH137;TH313文献标志码:A文章编号:1008-0813(2021) Influence of Medium Physical Parameters on the Hydraulic Performances of a Nuclear Main Pump LV Xue1,WANG Xiu-yong1,2,DU Yong-feng1,WANG Dong-shan1, LI Yi-bin1,2 (1.College of Energy and Power Engineering, Lanzhou University of Technology, Lanzhou730050, China; 2. Key Laboratory of Fluid Machinery and System of Gansu Province, Lanzhou730050, China) Abstract: In order to study the influence of medium physical parameters on the hydraulic performances of a nuclear main pump, the hexahedron structured grid was used, and based on the RNG κ- ε turbulence model, the changes of hydraulic performances of nuclear main pump with clear water and liquid sodium were compared and analyzed on the basis of steady calculation. The results show that the change of medium physical parameters has little influence on the velocity field in the pump, but the uniformity of velocity distribution decreases with the decrease of medium kinematic viscosity. Compared with water medium, when the conveying medium is liquid sodium, the head of nuclear main pump changes slightly, and the decrease amplitude of shaft power is greater than the decrease of density, so the efficiency is improved obviously. Key words: medium; physical parameters; nuclear main pump; hydraulic performance; numerical simulation 向小强1,王建成1,李建松2 (1.徐州重型机械有限公司技术中心,江苏徐州221004; 2.徐州工业职业技术学院工程装备智能制造技术研究开发中心,江苏徐州221140) 摘要:为了降低负载敏感型多路阀的体积和重量,提出了一种三通流量阀与溢流阀的集成设计方案。文中详细阐述了该集成阀的结构及原理,搭建了其液压仿真模型,并应用于某款工程机械产品的变幅系统,测试验证了其三通分流功能和溢流保护功能。进一步,讨论分析了集成阀的设定压差、阀芯过流孔径等关键参数对系统压损和工作效率有很大的影响,实际使用中需综合两者来选用该阀。 关键词: 负载敏感;三通流量阀;溢流阀;集成设计;仿真

中图分类号:TH137.9文献标志码:A文章编号:1008-0813(2021) Integrated Design and Application of Three-way Flow Valve and Overflow Valve XIANG Xiao-qiang1, WANG Jian-cheng1, LI Jian-song2 (1. Technology Center, Xuzhou Heavy Machinery Co., Ltd. of XCMG, Xuzhou221004, China; 2. Research and Development Center for Intelligent Manufacturing Technology of Engineering Equipment, Xuzhou College of Industrial Technology, Xuzhou221140, China) Abstract: In order to reduce the volume and weight of load sensitive multi-way valve, an integrated design scheme of three-way flow valve and overflow valve is proposed in this paper. The structure and principle of the integrated valve are described in detail, and its hydraulic simulation model is built. It is applied to the luffing system of a construction machinery product, and its three-way shunt function and overflow protection function are tested and verified. Further, it is discussed and analyzed that the key parameters such as the set differential pressure of the integrated valve and the overflow aperture of the valve core have a great impact on the system pressure loss and work efficiency. In practical use, the valve needs to be selected by combining the two factors. Key words: load-sensing; three-way flow valve; overflow valve; integrated design; simulation

张伟1,丘铭军1,李向辉1,王亚强1,田慧林2 (1.中国重型机械研究院股份公司,西安市重型机械高端液压技术与装备工程技术研究中心, 陕西西安710032; 2.日照钢铁有限公司板材炼钢制造部,山东日照276800) 摘要:该文提出一种高效实现传统板坯连铸机动态轻压下液压伺服设备改造的方案,可实现连铸机“边生产、边改造”,减少了改造成本,极大地缩短了改造停机时间。方案经模拟试验,试验结论证明方案控制精度高,运行稳定、可靠。利用该方案成功运用于工程实践,显著提升了企业的产品核心竞争力,为企业与社会带来了巨大的经济效益。 关键词:板坯连铸机;动态轻压下;模拟试验;液压伺服设备改造

中图分类号:TH137.9文献标志码:A文章编号:1008-0813(2021) Research and Application of High Efficiency Transformation Scheme for Dynamic Soft Reduction Hydraulic Servo Equipment of Slab Caster ZHANG Wei1, QIU Ming-jun1, LI Xiang-hui1, WANG Ya-qiang1, TIAN Hui-lin2 (1. China National Heavy Machinery Research Institute Co., Ltd., Xi'an Heavy Machinery High-end Hydraulic Technology and Equipment Engineering Technology Research Center, Xi'an710032, China; 2. Rizhao Iron & Steel Co., Ltd., Sheet Steel Manufacturing Department, Rizhao276800, China) Abstract: This paper proposes an efficient scheme for implementing the dynamic soft reduction of slab caster for the traditional slab continuous casting machine, which can realize the “one side production and one side modification”. The scheme reduces the cost of transformation and greatly shortening downtime for retrofitting. The scheme has undergone simulation experiments, and the results prove that the scheme has high control accuracy and stable operation. This method has been successfully applied in engineering practice, which has significantly improved the core competitiveness of enterprises and brought huge economic benefits to enterprises and society. Key words: slab continuous caster; dynamic soft reduction; simulation experiment; modification of hydraulic servo equipment

Isight在配流盘多目标优化设计中的应用 董正荣,成效先,崔凯,郭志敏 (林德液压(中国)有限公司,山东潍坊261205) 摘要:配流盘是轴向柱塞泵最关键的元件之一,其结构参数对轴向柱塞泵的振动噪声有着重大影响。该文以某双斜盘式轴向柱塞泵为研究对象,首先基于Catia软件二次开发方式计算配流盘通流面积比,然后基于AMESim软件建立该轴向柱塞泵的一维液压动力学仿真模型,其中采用受控节流阀模拟配流盘的通流面积比,最后基于Isight软件集成Catia和AMESim搭建配流盘多参数多目标联合仿真优化平台,并综合运用试验设计、近似建模和多岛遗传算法对该轴向柱塞泵进出口流量脉动幅值进行优化。 关键词: 配流盘;通流面积比;流量脉动;集成优化

中图分类号:TH137文献标志码:A文章编号:1008-0813(2021) Application of Isight in Multi-objective Optimal Design of Valve Plate DONG Zheng-rong, CHENG Xiao-xian, CUI Kai, GUO Zhi-min (Linde Hydraulics (China) Co., Ltd., Weifang261205,China) Abstract: Valve plate is one of the most important components of axial piston pump, whose structural parameters have a great influence on the vibration and noise of axial piston pump. In this paper, a double-swash-plate axial piston pump is taken as the research object. Firstly, the flow area ratio of the valve plate is calculated based on the secondary development method of CATIA software. Then, the one-dimensional hydraulic dynamics simulation model of the axial piston pump is established based on AMESim software, in which controlled throttle valve is used to simulate the flow area ratio of the valve plate. Finally, a multi-parameter and multi-objective co-simulation optimization platform was built based on Isight software integrating CATIA and AMESim, and the experimental design, approximate modeling and multi-island genetic algorithm were comprehensively used to optimize the inlet and outlet amplitude of flow pulsation of the axial piston pump. Key words: valve plate; flow area ratio; flow pulsation; integrated optimization

基于Simcenter 3D的轴向柱塞泵噪声预测 董正荣,成效先,崔凯,郭志敏 (林德液压(中国)有限公司,山东潍坊261205) 摘要:随着轴向柱塞泵高压、高速性能需求的提高,其振动噪声问题日益突出。该文以某双斜盘式轴向柱塞泵为研究对象,首先基于Simcenter 3D motion软件搭建该轴向柱塞泵的刚柔耦合多体动力学模型,然后基于Simcenter 3D motion和Simcenter AMESim软件搭建该轴向柱塞泵的1D & 3D液固耦合仿真模型,以获取吻合实际情况的前后壳体和中间端盖的动态激励载荷谱,最后基于Simcenter 3D Nastran软件模拟该轴向柱塞泵结构辐射噪声响应。 关键词:轴向柱塞泵;刚柔耦合;液固耦合;结构辐射噪声 中图分类号:TH137.5文献标志码:A文章编号:1008-0813(2021)12-0034-04 Noise Prediction of Axial Piston Pump Based on Simcenter 3D DONG Zheng-rong, CHENG Xiao-xian, CUI Kai, GUO Zhi-min (Linde Hydraulics (China) Co., Ltd., Weifang261205,China) Abstract: With the improvement of high pressure and high speed performance demand of axial piston pump, the vibration and noise problem becomes more and more prominent. In this paper, a double-swash-plate axial piston pump is taken as the research object. Firstly, a rigid-flexible coupling multi-body dynamics model of the axial piston pump is built based on Simcenter 3D Motion software. Then, based on Simcenter 3D Motion and Simcenter AMESim software, the 1D & 3D liquid-solid coupling simulation model of the axial piston pump was built to obtain the dynamic excitation load spectrum of the front and rear shell and the middle end cover consistent with the actual situation. Finally, the structural radiated noise response of the axial piston pump were simulated based on Simcenter 3D NASTRAN software. Key words: axial piston pump; rigid-flexible coupling; liquid-solid coupling; structural radiated noise

钱国会1,耿艳春2 (1.广州安卓机械科技有限公司,广东广州511340; 2.广州机械科学研究院有限公司,广东广州510700) 摘要:近年中国船舶、舰艇、海上平台等海事工业发展飞快。在这类重工平台和整车设备上设计大量的风道气路、水液管线和泵阀中道等法兰连接处的端面密封,其密封的可靠性,运行安全性和寿命周期的研究,是保障我国海工事业设计建造与长效运营的基础,也是我们海事装备今后更新叠代的设计依据;该文是以海事装备中管线连接法兰和设备端面的密封性能设计;纤维增强应用、无机材料填充预处理;交联硫化配方合成、密封元件的制坯成型等方面的工艺研究,制备一款基于橡胶垫,无石棉板综合性能更优秀的高性能纤维增强端面船用密封元件,来提升我国海事装备建造与运维水平,以及延长海况风道气路、管线泵阀等装备的端面密封周期。 关键词: 海事装备;端面密封;法兰连接;气液管线;纤维增强;无机填充 中图分类号:TH137文献标志码:A文章编号:1008-0813(2021)12-0038-05 Application Design and Formulation of High Performance Fiber Reinforced Marine End Face Sealing Element QIAN Guo-hui, GENG Yan-chun (1. Guangzhou Anzor Machinery Technology Co., Ltd., Guangzhou511340, China; 2. Guangzhou Mechanical Engineering Research Institute Co., Ltd., Guangzhou510700, China) Abstract: In recent years, China's maritime industries such as ships, naval vessels and offshore platforms have developed rapidly. On such heavy industry platform and vehicle equipment design of air duct gas path, tathagata liquid pipeline and water pump valve flange joint of end face seal, the sealing reliability, safety and life cycle of research, is the guarantee of our country construction and long-term operation in the design of Marine engineering career, also is our maritime equipment update in the future of the iterative design basis; This paper is based on the sealing performance design of pipeline connection flange and equipment end face in maritime equipment;Fiber reinforced application, inorganic material filling pretreatment; Crosslinking curing recipe synthesis, blocking the molding of the sealing technology research, preparation of a rubber mat, based no asbestos board more excellent comprehensive properties of high performance fiber reinforced Marine seal components, to enhance the level of China's maritime equipment construction and operations, as well as the extension of sea air duct gas path, such as equipment of end face sealing pipeline pump valve cycle. Key words: maritime equipment; end face seal; flange connection; gas and liquid pipeline; fiber reinforced; inorganic filler

高健1, (1.抚顺特殊钢股份有限公司,辽宁抚顺113001; 2.江苏科技大学,江苏镇江215600) 摘要:真空感应炉翻炉液压系统液压介质原设计使用水乙二醇,含有40%~45%水,炉内翻炉液压缸一旦渗油,真空度无法保证,合成脂肪酸酯无水阻燃介质是一种环保液压油,采用合成脂肪酸酯替换水乙二醇,既可以阻燃、安全环保又可以保证真空度,避免真空波动影响产品质量,通过在普通国产电渣炉换油试验,3次检测结果证明水乙二醇可以用脂肪酸酯无水阻燃替换,利用检修时间对真空感应炉进行换油,生产后运行良好,防止液压系统漏油造成真空波动进而影响生产和产品质量。 关键词:真空感应炉;水乙二醇;无水脂肪酸酯液压油;无水脂肪酸酯液压油替换水乙二醇 中图分类号:TH137文献标志码:A文章编号:1008-0813(2021)12-0043-04 Research on Replacing Anhydrous Fatty Acid Ester Hydraulic Oil with Water Glycol for Vacuum Induction Melting Furnace GAO Jian1, WANG Xiu-jun1, LIU Xuan1, ZHANG Xin-yu2 (1. Fushun Special Steel Co., Ltd., Fushun113001, China; 2. Jiangsu University of Science and Technology, Zhenjiang215600, China) Abstract: The hydraulic medium of the hydraulic system of the vacuum induction melting furnace tilting was originally designed to use water glycol, containing 40%~45% water. Once the hydraulic cylinder for tilting leaks, the vacuum parameters cannot be guaranteed. The anhydrous fatty acid ester is a kind of environmental anhydrous flame retardant hydraulic oil. The anhydrous fatty acid esters is used to replace water glycol, which can be flame-retardant, safe and environmental, and can ensure the vacuum parameters, and avoid vacuum fluctuations affecting product quality. It has passed the oil change test in ordinary domestic ESR furnaces. The test results proved that water glycol can be replaced with anhydrous fatty acid ester anhydrous flame retardant by 3 times inspection results. The hydraulic oil of the vacuum induction melting furnace was replaced during the maintenance time. It works well since it is put in production. It can prevent the hydraulic system from leaking and avoiding vacuum fluctuations which can cause to affect production and product quality. Key words: vacuum induction melting furnace; water glycol; anhydrous fatty acid ester hydraulic oil; anhydrous fatty acid ester hydraulic oil instead of water glycol

郭仁发 (武汉自动控制阀门厂,湖北武汉430012) 摘要:该文给出“液压变压器”的定义,阐述其对于恒压液压网络的重要性,并对“液压变压器”这一词条释义不清、归类错乱、容易引起误读的现状进行了梳理。同时推介一项发明专利:“一种液压变压器” (专利号:ZL201510618343.9),简述其技术优势。在此基础之上,展望了液压变压器技术应用推广的前景:恒压液压网络将成为液压领域进步、发展的基调和主旋律。“恒压液压网络”是一个规范的、统一的系统,高新科技、人工智能、数字化技术、工业4.0需要这样坚实的平台方能平稳落地,精准对接。 关键词: 液压变压器;恒压液压网络;8343液压变压器;应用前景 中图分类号:TH137文献标志码:A文章编号:1008-0813(2021)12-0046-04 Revisiting the Application Prospect of Hydraulic Transformers GUO Ren-fa (Wuhan Automatic Control Valve Co., Wuhan430012, China) Abstract: We define Hydraulic Transformers and elaborate its importance to hydraulic constant pressure network systems. We clear up the common misconceptions on Hydraulic Transformers, often due to ambiguous definitions, improper categorizations, and other misconception-prone situations. We highlight one invention patent “A Specific Hydraulic Transformer” (Patent number: ZL201510618343.9). We briefly describe its technical pros. On this basis, we lay out the application prospect of Hydraulic Transformers-hydraulic constant pressure network systems will be the main area of innovations. Hydraulic constant pressure network systems offers a well-defined and unified framework that incorporates new and high technology, artificial intelligence, digitalization, and Industry 4.0. Key words: hydraulic transformers; hydraulic constant pressure network systems; 8343 hydraulic transformers;application prospect

姚泽功,王秀艳,刘洋 (湖北江山专用汽车有限公司 技术中心,湖北襄阳441004)

摘要:运用COMSOL Multiphysics软件模拟了强压缸中液压油在截止阀腔体中流动过程,考察了液压油在以 关键词:截止阀;液压油;流体流动;密封 中图分类号:TH137文献标志码:A文章编号:1008-0813(2021)12-0050-05 Flow Pattern Analysis of Hydraulic Oil in Stop Valve of High Pressure Cylinder YAO Ze-gong,WANG Xiu-yan,LIU Yang (Technical Center, Hubei Jiangshan Special Purpose Vehicle Co., Ltd., Xiangyang441004, China)

Abstract: The flow process of hydraulic oil in a high

pressure oil cylinder in the stop valve cavity is simulated by COMSOL

Multiphysics software. The effects of opening degree of stop valve on the fluid

flow rate and temperature around the stop valve stem are investigated when the

hydraulic oil flew into the stop valve at Key words: stop valve; hydraulic oil; fluid flow; sealing

赵杏新,屠桂诚 (融彻智能科技(上海)有限公司技术部,上海201709) 摘要:弯轴柱塞马达常用来作为静液压行走驱动的主要执行元件,部分柱塞马达具有零排量的结构,便于在多马达系统中采用零排量功能将马达切出系统,该文通过分析弯轴柱塞马达在不同排量与转速下的功率损失数据,特别在零排量的工况下,以工程机械常见的一泵四马达行走驱动系统为例,通过不同构建的驱动类型所产生的功率损失对工程机械系统总功率损失的影响,经过试验数据对比,提出降低系统总功率损失并提高工程机械总运行效率的系统设计。 关键词:工程机械;弯轴柱塞马达;零排量;离合器;功率损失 中图分类号:TH137文献标志码:A文章编号:1008-0813(2021)12-0055-03 Power Loss Analysis of Bent Axis Motor with Zero Displacement ZHAO Xing-xin, TU Gui-cheng (Rocher Intelligent Tech.(Shanghai) Co., Ltd., R&D Department, Shanghai201709, China) Abstract: Bent axis motor normally applied as hydrostatic propel for off highway machines. Some of motor with zero displacement will be controlled at zero position when needed. Power loss at different displacement and working speed of bent axis motor was analyzed. Especially, when motor worked at zero displacement, one pump and four motor propel system, different system design have big impact on machine total power loss. Based on the test data analysis, proposed the best efficiency means least power loss solution for off highway machine propel system. Key words: off-highway machine;bent axis motor;zero displacement;clutch;power loss

罗涛 Application of Closed Circuit Hydraulic System for Reciprocating Gas Booster LUO Tao (北京杰利阳能源设备制造有限公司) 摘要: 简述了闭式液压系统的工作特性,以及用于驱动往复式气体增压器时,相对于开式液压系统的应用优势及局限性,为液驱增压设计方案提供参考。 关键词: 闭式;液压;增压;应用 中图分类号:TH137;TH138文献标志码:B文章编号:1008-0813(2021)12-0057-03

>基于AMESim对液压系统低压告警仿真分析 金磊,王勇彬,刘政宏 Analysing of the Aircraft Hydraulic System Failure Warning Based on AMESim JIN Lei, WANG Yong-bin, LIU Zheng-hong (1.中航西安飞机工业集团股份有限公司,陕西西安710089; 2.空装驻西安地区第一军事代表室,陕西西安710089) 摘要:该文针对大流量需求时出现短时系统低压现象进行故障分析,通过飞机不同姿态下液面相对吸油口位置,及运用AMESim软件对飞机液压系统建模,开展故障模拟及机理分析,定位液压系统低压告警故障原因为油箱增压系统异常,并给出了改进措施。 关键词:液压系统;低压告警;AMESim 中图分类号:TH137文献标志码:B文章编号:1008-0813(2021)12-0060-04

李勇键,吴俊逸,邓昊,易鑫,陈云周 Static Stress Analysis of Compression Cylinder Used in Large Waste Compression Station LI Yong-jian,WU Jun-yi,DENG Hao,YI Xin,CHEN Yun-zhou (中联重科湖南特力液压有限公司,湖南常德415106) 摘要:以某型大型垃圾压缩站用压缩油缸为研究对象,基于有限元建立的几何模型进行静应力分析,校核油缸的缸筒在活塞杆伸出状态时耳座部位的静应力,为压缩油缸的设计与优化提供参考。 关键词:油缸;压缩油缸;静应力;有限元 中图分类号:TH137文献标志码:B文章编号:1008-0813(2021)12-0063-04

胡小冬1,李会妨2,刘莹莹2,杨建春1 (1.徐州重型机械有限公司零部件研究所,江苏徐州221004; 2.江苏汇智高端工程机械创新中心有限公司,江苏徐州221004) 摘要:针对平衡阀控制端阻尼对起重机卷扬抖动的影响,该文采用AMESim仿真软件,搭建了起重机卷扬液压系统仿真模型。通过对含有三种不同控制端阻尼组合的系统进行仿真,得出了卷扬下落性能最优的平衡阀控制端阻尼组合及大小,为解决实际应用中起重机卷扬抖动问题提供了方向与支撑。 关键词:平衡阀;阻尼;卷扬抖动;仿真 中图分类号:TH137文献标志码:A文章编号:1008-0813(2021)12-0067-04 Study on the Influence of Balance Valve Control Side Damping on Crane Winch Jitter HU Xiao-dong1, LI Hui-fang2, LIU Ying-ying2, YANG Jian-chun1 (1. Part Research Institute of Xuzhou Heavy Machinery Co., Ltd., Xuzhou221004, China; 2. Jiangsu Advanced Construction Machinery Innovation Center Co., Ltd., Xuzhou221004, China) Abstract: Focus on the influence of balance valve control side damping on crane winch jitter, the crane winch hydraulic system simulation model is established by using AMESim software. Through the simulation of the system with three different combinations of control side, the control side damping combination and size of the balance valve with the best winch falling performance are obtained, which provides direction and support for solving the problem of crane winch jitter in practical application. Key words: balance valve; damping; winch jitter; simulation

武兴瑞 (太重集团榆次液压工业有限公司,山西晋中030600) 摘要:该文主要介绍了在供配电系统中,在液压系统中通过电气自动化控制来满足液压系统在工业上的应用需求。通过PLC自动化来实现液压系统中所要求的电气连锁,以及对各个部分的控制,从而实现了液压系统的高效运行。 关键词:电气自动化;液压系统;PLC自动控制;电气连锁 中图分类号:TH137文献标志码:A文章编号:1008-0813(2021)12-0070-04 Electric Automatic Control Design of Hydraulic System WU Xing-rui (Taizhong Group Yuci Hydraulic Industry Limited Company, Jinzhong030600, China) Abstract: This paper mainly introduces in the power supply and distribution system, in the hydraulic system, through the electrical automation control to meet the application needs of the hydraulic system in industry. Through PLC automation to achieve the hydraulic system required by the electrical chain, as well as the control of each part, so as to achieve the efficient operation of the hydraulic system. Key words: electrical automation; hydraulic system; PLC automatic control; electrical interlocking

郭志敏,董致新 (林德液压(中国)股份有限公司,山东潍坊261061) 摘要:针对工程机械柴油机工况剧烈变化导致的燃油效率低下问题,以液压挖掘机为应用平台,设计了采用闭式泵和蓄能器的液压混合动力单元。该单元主要控制目标为平衡主轴功率,使柴油机工作在高效区域,进而降低整机油耗。利用仿真模型对混合动力单元的蓄能器预充压力、蓄能器容积和闭式泵排量等关键参数进行多参数组合批处理分析,通过不同参数组合的油耗结果,得到油耗最佳参数组合。经过参数优化的混合动力单元在不改变原有液压系统的前提下,实现最大节油4.13%。 关键词: 混合动力;柴油机;油耗;节能;仿真 中图分类号:TH137文献标志码:A文章编号:1008-0813(2021)12-0074-06 Optimization of Key Parameters on Hydraulic Hybrid Unit GUO Zhi-min, DONG Zhi-xin (Linde Hydraulics (China) Co., Ltd., Weifang261061, China) Abstract: In order to solve the problem of low fuel efficiency of the diesel engine, which caused by the volatility working condition of construction machinery, a hydraulic hybrid unit is designed based on an excavator. This unit includes a closed pump and an accumulator. It stabilizes the engine power, makes the diesel engine working in the high efficiency area, and finally reduces the fuel consumption. The key parameters of the hydraulic hybrid unit are analyzed by multi parameters batch processing of a simulation model, such as accumulator pre charging pressure, accumulator volume and closed pump displacement. Through the fuel consumption results of different combinations, the best parameter combination is obtained. Without changing the original hydraulic system, the optimized hybrid unit achieves the maximum fuel saving of 4.13%. Key words: hybrid power; diesel engine; fuel consumption; energy saving; simulation

装卸料机C推杆泄漏率超标原因分析及处理 苗润泽 (中核核电运行管理有限公司,浙江海盐314300) 摘要: 重水堆装卸料机在换料过程中多次出现C推杆泄漏率超标导致C推杆驱动失效的问题,该文通过介绍C推杆回路的密封方式和C推杆驱动原理,并结合现场检修实践经验,分析了影响C推杆泄漏率超标的原因及处理方法。通过这些措施的实施,可以有效地减少C推杆失效次数,提高了换料过程中C推杆的稳定性,并取得了较为理想的效果。 关键词:C推杆;失效;泄漏率;超标;原因分析 中图分类号:TB42;TM623文献标志码:A 文章编号:1008-0813(2021)12-0080-03 Fuelling Machine C Ram Leakage Rate Exceeding the Standard Analysis and Treatment MIAO Run-ze (CNNC Nuclear Power Operation Management Co., Ltd.,Haiyan314300, China) Abstract: In heavy water reactor, the problem of C ram drive failure caused by excessive leakage rate of C ram occurred many times when refueling of fuelling machine. The article introduces circuit sealing structure and driving principle of C ram, and analyzes the cause and treatment of the leakage rate exceeding the standard of C ram based on the practical experience of field maintenance. Through the implementation of these measures, it can effectively reduce the failure times of C ram improve the stability of C ram in the process of refuelling, and and it has achieved good effect. Key words: C ram; failure; leakage rate; exceeding the standard; cause analysis

陈云周,易鑫,吴俊逸 (中联重科湖南特力液压有限公司,湖南常德415106) 摘要:该文通过理论分析与实验相结合的方法,研究了臂架油缸缸底焊后免镗工艺。分析表明:利用普通镗床加工的缸底零件,其尺寸精度不能满足免镗要求。传统的一夹一顶的装夹方式跳动大于1mm,远大于精加工误差。焊后形位公差检测采用三坐标效率低下。为确保缸底耳环达到焊后免镗要求,必须采取合理的零件加工工艺、焊接工艺,设计专用装夹工装及快检工具等工艺措施。实验结果表明,该文拟定的工艺方案完全达到了设计要求,并已投入焊接生产。 关键词:臂架;油缸;免镗;焊接工艺;装夹工装;快检工具 中图分类号:TH137文献标志码:A文章编号:1008-0813(2021)12-0083-06 Research on Non-boring Technology of Arm Frame Cylinder Welding Bottom Earrings CHEN Yun-zhou, YI Xin, WU Jun-yi (Zoomlion Hunan Teli Hydraulic Co., Ltd., Changde415106, China) Abstract: In this paper, the boring-free process after the bottom welding of the boom cylinder is studied by the combination of theoretical analysis and experiment. The analysis shows that the dimensional accuracy of cylinder bottom parts processed by ordinary boring machine cannot meet the requirements of boring-free. The traditional clamping method with one clamp and one top jumps more than 1 millimeter, which is far greater than the finishing error. The efficiency of using three coordinates for post-Weld form and position tolerance detection is too low. In order to ensure that the earrings at the bottom of the cylinder meet the requirements of boring-free after welding, reasonable processing technology, welding technology, design of special clamping tools and quick inspection tools and other technological measures must be taken. The results show that the process scheme proposed in this paper fully meets the design requirements and has been put into welding production. Key words: arm frame; cylinder; boring-free; welding process; clamping tool; quick inspection tool

杨凯1,2,刘伟1,2,张红涛1,2,付静1,2 (1.河南航天工业总公司,河南郑州451191; 2.河南航天液压气动技术有限公司,河南郑州451191) 摘要:该文主要介绍了一种高速高压离心泵的设计要点,新型技术及创新点的应用。 关键词:高速高压离心泵;增速箱;平衡孔;设计 中图分类号:TH137文献标志码:A文章编号:1008-0813(2021)12-0088-03 Design and Research of a High Speed and High Pressure Centrifugal Pump

YANG Kai1,2,LIU

Wei1,2,ZHANG

Hong-tao1,2,FU

Jing1,2 (1. Henan General Company of Astronautics Industry,Zhengzhou451191, China; 2. Henan Aerospace Hydraulic & Pneumatic Technology Co., Ltd., Zhengzhou451191, China) Abstract:This paper mainly introduces the design poits, new technology and innovative application of a high-speed and high-pressure centrifugal pump. Key words: high speed and high pressure centrifugal pump; speed increase gearbox; balance hole; design

|

|||||||||

|

版权所有: 中国液压气动密封件工业协会 地址:北京市西城区太平街甲2号 邮编:100050

电话:010-63172781 传真:010-63172781 E-mail: chpsa-yqm@163.com 京ICP备05039448号 国际统一刊号:ISSN 1008-0813,国内连续出版物号:CN11-4839/TH 邮发代号:82-152,国外代号:BM4757 |

|||||||||